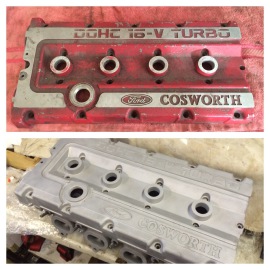

Sand / Bead Blasting

Here at AC Restoration Services we are fortune to own a Brand New SBC420 Sand Blasting Cabinet. This provides a very modern and efficient cleaning process. At the minute we are using a Medium Glass Grit which is ideal for painted wheels, heavily rusted or corroded parts and even powder coated parts. The dimensions of this Cabinet are L= 1210mm, H (from Grill) 570mm D= 600mm.

About Sand Blasting and How it Works..

Sand or dry blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically air is used to propel the blasting material, often called the media.

What Is Sand Blasting Used For?

Abrasive Grit Blasting or Sand blasting is a more aggressive form of blast cleaning and can be used on harder metals such as Cast Iron, mild steel and alloy metals,

Regular work includes cast Iron benches, lawnmowers. and fireplaces. Mild steel examples include suspension components, motor bike frames and Steel/Alloy Wheels.

If you are not sure what blast cleaning process you require please feel free to contact us for friendly helpful advice. Just let us know what you have that requires cleaning and the finish you require. We will do the rest.