Cleaning Processes we offer here at AC.

Here at AC Restoration Services we offer a number of high tech industrial cleaning processes. These processes range from Cabinet Blasting, Aqua/Vapour Blasting, Soda Blasting, Sand Blasting, to High Frequency or Ultra Sonic Cleaning

Click on any of the images below to find out more about how these hi-tech cleaning services that we offer work.

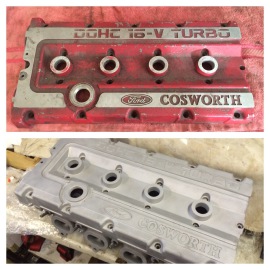

Vapour/Aqua Blasting - Aqua blasting is a process of cleaning parts back to their original 'as new' finish. Also known as Vapour blasting or Wet blasting. Various media is used to achieve the correct finish to the metal. The media is forced under pressure with hot water to give a silky satin finish which can then be painted, laquered or left bare. This process is not as harsh as dry blasting so can be used on delicate items such as carburetors. Aqua blasting is suitable for all non ferrous metals including Aluminium, Magnesium, Titanium, Brass, copper and Stainless Steel.

Sand/Dry Blasting - Sand or dry blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically air is used to propel the blasting material, often called the media.

Ultra Sonic Cleaning - Another service we offer, which compliments Vapour Blasting, is Ultrasonic Cleaning. Ultrasonic Cleaning uses high frequency sound waves through liquid to effectively remove dirt and contaminants such as stale fuel and dirt, We usually Ultra Sonically clean parts after Aqua Blasting to be assured that no media is left inside the parts.